The Shape of Water

Finn Erik Mohn Berge, Hammertech AS, Norway, outlines one choice of plug and play meter that can measure water fractions, water-cuts, gas fractions and salinity without the need for pressure, volume and temperature information.

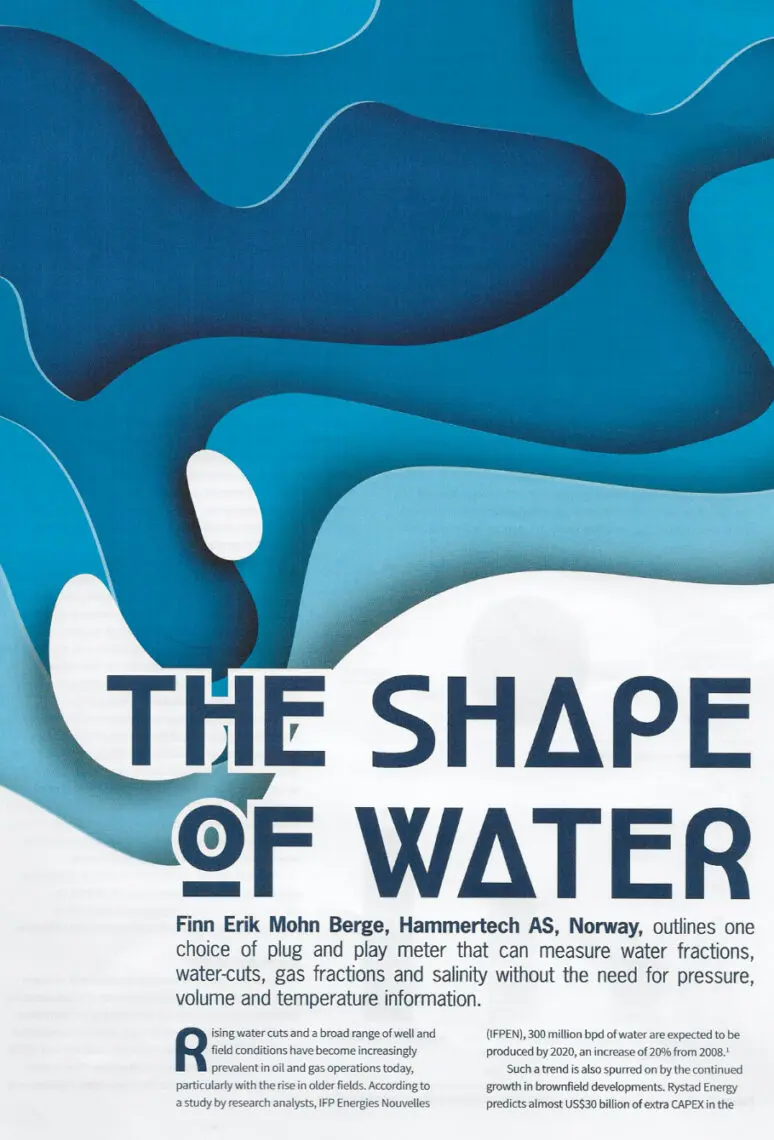

Rising water cuts and a broad range of well and field conditions have become increasingly prevalent in oil and gas operations today, particularly with the rise in older fields. According to a study by research analysts, IFP Energies Nouvelles (IFPEN), 300 million bpd of water are expected to be produced by 2020, an increase of 20% from 2008. (figure 1)

Such a trend is also spurred on by the continued growth in brownfield developments. Rystad Energy predicts almost US$30 billion of extra CAPEX in the engineering and procurement (E&P) subsea segment over the next 6 years with the majority of expenditure directed to brownfield sites?

With all produced water requiring treatment, management and either disposal or reuse, along with the significant costs, environmental issues and the need to measure water production and water salinity in real time for production optimisation, how to maximise water reuse and minimise costs and risks has become a critical question.

Yet, are today's technologies giving operators the information they need on produced water?

This article provides an overview of a plug and play meter that can measure water fractions, water-cuts, gas fractions and salinity all within one instrument without the need for pressure, volume and temperature (PVT) information. Figure 1 highlights the difference between water fraction measurements and water-cut measurements. The meter reduces CAPEX, which is approximately one fifth of the cost of traditional multiphase meters, and OPEX as maintenance requirements and their frequency are relatively low compared to alternative meters on the market.

Two very different choices

Operators are often left with two stark choices, neither of which meets their needs.

On one side, there are low-cost water-cut meters that generally do not work in multiphase flow and traditional well testing. While water-cut meters are able to provide real time measurements across the full range of water cuts, they come with significant data gaps in only providing information in water and oil rather than multiphase flow.

Furthermore, when it comes to traditional well testing, crews will test a well only once a month on average, with data being generated and interpreted one well at a time. This opens up significant vulnerabilities if a water breakthrough takes places just after a well test, with potentially over a month of non-detection. On the other side, there is the more complex multiphase meter.

While able to provide comprehensive multiphase flow information and accurately characterise flow regimes with often a 0 - 100% water in liquid ratio (WLR), such meters are often cumbersome, expensive, and require considerable maintenance.

Multiphase meters also rely on the accurate input of PVT data and other fluid parameters to achieve the specifications provided by vendors This can be a challenging process, especially as such variables are likely to change significantly over the lifetime of the reservoir as fluid and process conditions change.

Increased liquid and water in the gas flow, higher water cuts, mixed well streams or differences in salinity between injected and reservoir water can all have an impact on PVT properties. With the new meter, however, there is no complicated set-up or configurations and no reliance on PVT data.

A new water management solution

It is against this context that Hammertech AS has introduced a new water management solution that bridges the alternatives documented above.

The AquaField™ Multiphase Fraction and Salinity Meter provides full fraction measurements of the different phases of the well. This includes water fraction (hold-up), WLR, gas fraction measurement and salinity measurement. The meter requires no inputs from the operator, which means there is no sampling, laboratory analysis or updating of the meter required. This results in a significant reduction in OPEX due to its simplicity and robustness. Furthermore, the new meter costs approximately a fifth of a traditional multiphase meter price and it can be installed on every well.

By continuous measuring of the fractions of oil, water and gas, the operator can trend the well, and if there are no changes (or a slight steady increase in water), they can be confident that the well is stable and producing as expected. In such cases, expensive well testing is not required.

As soon as a change is measured in the well, such as a rapid increase in water or gas, the operator can then dispatch a well testing crew to investigate, instantly pinpointing problematic wells and instigating immediate remedial action.

This provides a contrast to traditional manual sampling in identifying the source of the water, such as produced formation water or injected water. With the new meter, the operator can access online salinity measurements, thereby identifying if the produced water is from the formation or the result of hard water injection that causes water injection breakthrough. This also saves time and costs of generating accurate and consistent measurements, and negates the need for personnel to travel to hazardous areas.

Furthermore, the meter does not include radioactive elements and has no moving parts, which leads to low maintenance, lower regulatory hurdles and no time-consuming or expensive requirements for calibration.

Operator value

The result is a complete reservoir management overview providing online, real time measurement of all phases at the wellhead, real time water salinity trending, the immediate identification of water breakthrough, and a pre-empting of the danger of separator water flooding. With low cost online measurements, operators can also remove their manual footprint and evolve towards the automation/digitisation of the field.

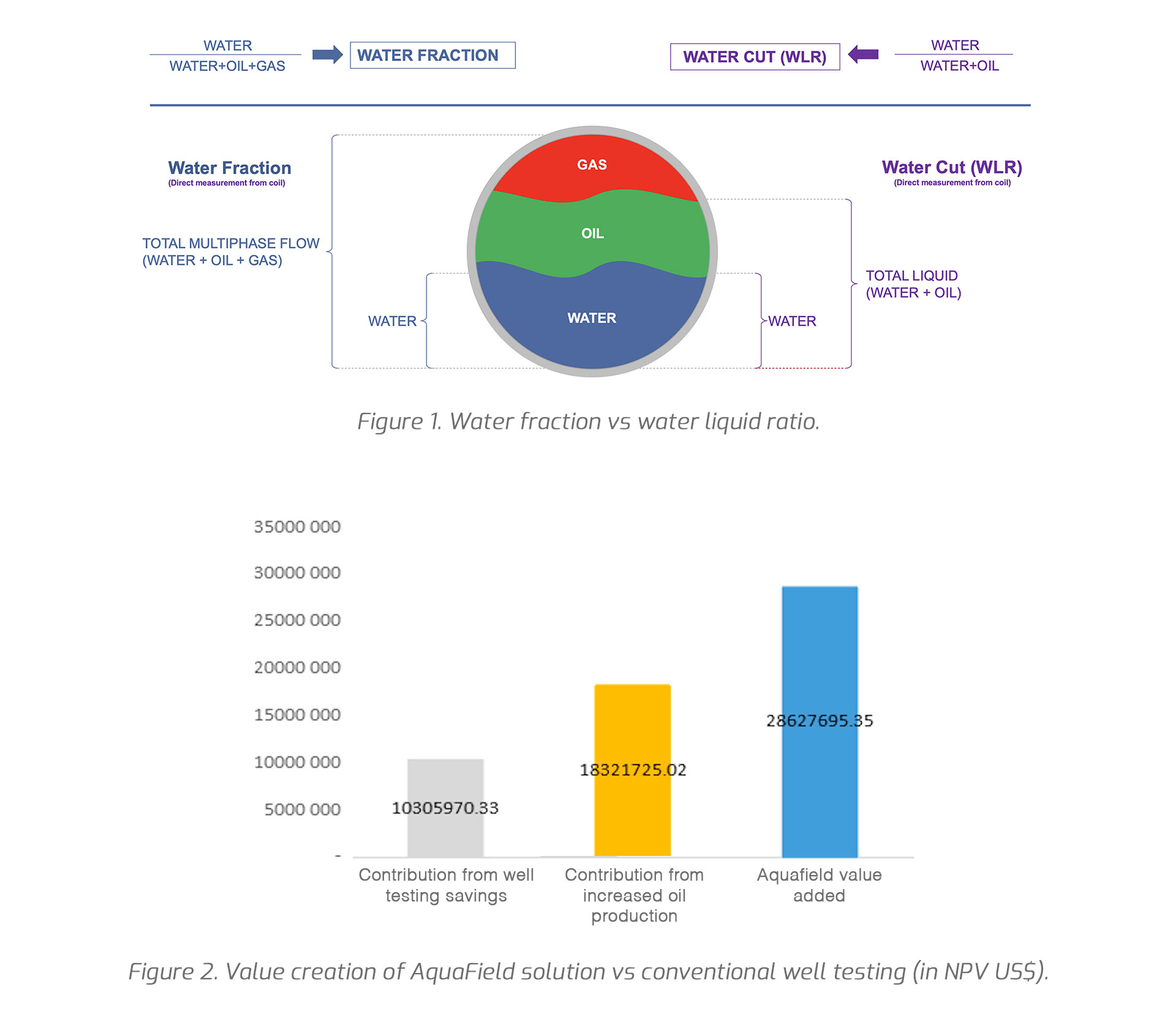

Another benefit is reduced CAPEX and OPEX with the costs of the meter equal to just two to three well tests, allowing the operator to access online measurements from each production well. Well test savings combined with increased oil production due to reduced water production can result in US$29 million in added value as Figure 2 illustrates, based on a field of 200 wells with an average production of 500 bpd, and a conservative oil price of US$55 (the price for Brent crude at the time of writing is US$63).

The high frequency magnetic field technique

The detection principle behind the new technology measures the water content and water conductivity in the flow using a compact, robust and non-intrusive sensor based around the high frequency magnetic field technique (HFMFT).

HFMFT is a variant of the eddy current measurement technique where an eddy current creates a magnetic field that opposes the change in the magnetic field that created it. The eddy currents then react back on the source of the magnetic field (Lenz's law).

When a conductor (in this case, the water) is exposed to a varying magnetic field, eddy currents are induced in the water. These currents create a magnetic field which opposes the original field and power is lost, due to the eddy currents in the water portion of the multiphase flow.

The loss of power is proportional to the water content, with large amounts of water resulting in large amounts of energy loss and small amounts of water resulting in small amounts of energy loss. The conductivity (salinity) of the water will also affect the energy loss.

The sensor then measures via a dedicated probe the conductivity (salinity) of the water to differentiate between energy loss caused by the amount of water or energy loss caused by levels of conductivity.

Conductivity is then calculated for the water in multiphase flow based on the measured complex permittivity of the water. As opposed to traditional water-cut meters, one of the special features of the meter is that it not only measures the WLR, but also the water fraction (hold up).

The combination of these two measurements is unique and other measurements such as the gas fraction can thereby be derived from this.

Strong testing performance

To date, the meter has gone through a series of testing and installations, with tests having demonstrated uncertainty specifications of water fraction and WLR at + 3% abs, and conductivity (salinity) at + 0.5 S/m.

Tests have included several internal tests at third party loops and external blind tests, such as at the flow loop facility at the Christian Michelsen Research (now NORCE) with a leading operator, a blind test with a supermajor oil service company, a joint test programme with Shell, Total and Equinor at the DNV GL flow loop facility in the Netherlands, and field trials offshore Alaska.

Increased revenue and higher recovery rates

With the growth in water management in oil and gas operations, a viable alternative to traditional well testing, water cut and multiphase meter operations have appeared at just the right time, generating real time multiphase fraction and salinity measurements.

The result will be increased revenue due to reduced water production, ultimately higher recovery rates, and a highly effective approach to water management at a time when it is clearly needed.

References

- Total, 'Five barrels of water for one barrel of oil', https://www.cnbc.com/ advertorial/2017/11/13/five-barrels-of-water-for-one-barrel-of-oil.html, (13/11/2017).

- Proserv, 'Proserv prepares for subsea supply chain tightening as demand spikes, https://www.proserv.com/subsea-supply-chain-tightening-as-demand-spikes/