A new approach to Middle East water management

Finn Erik Mohn Berge, Hammertech AS, discusses a commercially viable alternative to traditional well testing, water cut and multiphase meter operations, which can result in reduced water production, and ultimately higher recovery rates.

WITH THE GROWTH in enhanced oil recovery projects in mature fields, rising water cuts and a broad a range of well and field conditions, water management in the Middle East is becoming an increasingly important factor in oil and gas operations.

Such a trend is also likely to continue with the continued growth in brownfield developments. Rystad Energy predicts almost US$30bn of extra capital expenditure in the E&P subsea segment over the next six years, with the majority of expenditure directed to brownfield sites. The same is the case onshore, where Wood Mackenzie estimates that upstream capital investment across the Middle East is expected to rise by nine per cent year-on-year to US$56bn – with much targeted at brownfield sites.

With all produced water requiring treatment, management and either disposal or reuse – alongside the significant costs, and production and environmental issues – how to maximise water reuse and minimise costs and risks has become a critical question.

There is also a need for operators to measure water production and water salinity in real-time. Such information plays a vital role in steering reservoir management and well optimisation strategies – ensuring that water doesn’t gather in pipelines and inhibit oil production, that re-injected water is pushing oil to the centre of producing wells, and that threats to production from water salinity, such as water breakthrough, corrosion and hydrates, are pre-empted.

Choosing between two extremes

Yet are today’s technologies giving operators the information they need when it comes to produced water?

Too often, operators are left with two stark choices – neither of which really meet their needs.

On one side, there are low cost water-cut meters that generally don’t work in multiphase flow, and traditional well testing. While watercut meters are able to provide real time measurements across the full range of water cuts from 1-100 per cent, they come with significant data gaps in only providing information in water and oil rather than in multiphase flow.

When it comes to traditional well testing, well testing crews will – on average – test a well only once a month (sometimes the testing frequency is even longer) with data generated and interpreted one well at a time. Yet, what happens if a water breakthrough takes places just after a well test? In such cases, there is a real danger that water could be filling up the pipelines and separators without the operator knowing about it for over a month or more.

On the other side, there is the more complex multiphase meter. While providing comprehensive multiphase flow information and accurately characterising flow regimes, such meters are often cumbersome, expensive, and require considerable maintenance with the need to input pressure, temperature, volume (PVT) information. It is also economically unfeasible to deploy one multiphase meter on each well.

In summary, operators have one alternative providing incomplete water production information and the other being too expensive and complex. Not an ideal solution!

A new water management solution for the Middle East

It is against this context that Norwegianbased company Hammertech AS has introduced a new innovative water management solution to the Middle East region. The AquaField Water Fraction and Salinity Meter provides direct, robust, and costefficient water fraction and water salinity detection topside (with a subsea version likely to be released in the next few years). The AquaField, which can be placed on every well, also detects changes in multiphase flow and gas, due to its ability to track both total water content and salinity.

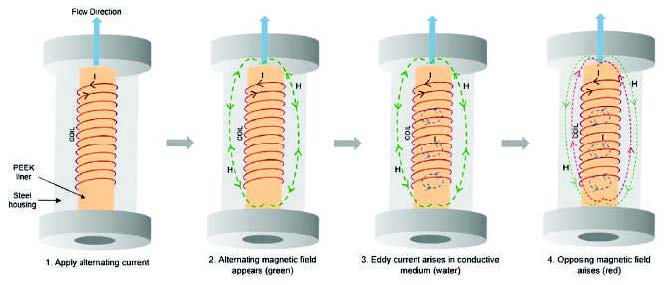

The technology behind the AquaField’s measurement principle is called the High Frequency Magnetic Field Technique (HFMFT) – a variant of the eddy current measurement technique where an eddy current creates a magnetic field that opposes the change in the magnetic field that created it.

The eddy currents then react back on the source of the magnetic field (Lenz's law). When a conductor – in this case the water – is exposed to a varying magnetic field, eddy currents are induced in the water. These eddy currents induce a magnetic field which opposes the original field and power is lost, due to the eddy currents in the water but only in the water portion of the multiphase flow. The loss of power is proportional to the water content, with large amounts of water resulting in large amounts of energy loss and small amounts of water resulting in small amounts of energy loss. The salinity of the water will also affect the energy loss.

The AquaField then measures the water salinity and differentiates between energy loss caused by the amount of water or energy loss caused by the different levels of salinity. Salinity is then calculated for the water in multiphase flow based on the measured complex permittivity of the water. To date, all tests of the AquaField have demonstrated uncertainty specifications of water fraction at ± five per cent (with recent tests showing closer to ± three per cent) and salinity at ± 0.5 S/m.

A complete overview and increased production

The result for the operator is a complete overview of the field through the online trending of water content in multiphase flow. By measuring water fractions, the operator can trend the water level, and if there are no changes (or a slight steady increase), they can be confident that the well is stable and producing as expected. In such cases, expensive well testing crews aren’t required.

As soon as there is a change in the water level, however (as detected by the Aquafield) then the operator can dispatch a well testing crew to investigate, instantly pinpointing problematic wells (such as when there is excessive water production from the wellhead) and instigating immediate remedial action.

Furthermore, since the AquaField also detects the salinity of the water, the operator can identify immediately if the water production is a result of too hard water injection. This is because the salinity of the injected water and the produced water is different.

The result is online, real-time measurement at the wellhead; real-time water salinity trending; the immediate identification of water breakthrough; and a pre-empting of the danger of separator water flooding. We also conservatively estimate an increase of 0.5% per cent in production from the AquaField, providing a significant impact on investment returns from often mature assets.

Cutting down costs, simplifying deployments

Another key benefit of the AquaField is reduced CAPEX and OPEX as well as ease of deployment.

The costs of the AquaField are equal to just two to three well tests, providing the operator with the ability to have online water fraction and salinity detection capabilities on each production well. Well test savings combined with increased oil production can result in US$29mn in added value, based on a field of 200 wells, with an average production of 500 bpd, and a very conservative oil price of US$55.

The lightweight simple, non-intrusive ‘plug and play’ design of the AquaField is also significantly more cost-effective compared to complex multiphase meter deployments.

According to our estimates, replacing an installation of a multiphase meter per well on a five-well configuration, with an installation of a combination of one AquaField per well and a multiphase meter on the manifold can lead to savings of up to US$500,000. For a typical field with 50 wells using this configuration, the savings can be more than US$5mn – all simply down to replacing technologies.

Furthermore, the fact that the meter is not dependent on PVT data, doesn’t include radioactive elements, and has no moving parts ensures low maintenance, lower regulatory hurdles and no time consuming and expensive requirements for calibration.